From Automation to Hazardous Waste Disposal: How Can Manufacturing Companies Go Green?

From Automation to Hazardous Waste Disposal: How Can Manufacturing Companies Go Green?

Manufacturing companies produce a lot of waste each year and while it’s obvious that care must be taken to avoid causing environmental issues, it’s not always clear how to go about this. Fortunately, there are teams of people working to figure out how to make it easier for companies to be eco-friendly while continuing to produce their products.

Make Everyone Part of the Solution

Both employees and customers can be part of the solution. First, employees should be educated on the company policies, which really should include as many eco-friendly practices as possible. Ideally, the company should focus on how to be greener and then make it a part of everyday work life. Reducing waste, improving efficiency, and lowering your commercial carbon footprint can be just a few of the things that employees can influence.

You can also encourage customers to be more eco-friendly by adding recycling reminders to packaging, promoting green practices in newsletters and social media, and including tips on helping them stay green, too.

Keep Facilities Updated

Factories and manufacturing plants that were built decades ago are not the cleanest places on earth. In fact, many only do the bare minimum to stay on top of the newest regulations and bylaws. To truly go green, it may require a complete overhaul of your building and systems.

Newer machines and equipment will use less energy and have lower carbon footprints than older models, so updating them can save money and reduce environmental hazards. Automation can make things even greener and more efficient, so the processes require less power than when everything is done by humans.

Change Up Your Cleaning Habits

Industrial spaces need heavy-duty cleaning and that means chemicals in many cases. However, it’s possible to change this up and use green products instead. You will need to focus on what is best for the world around you and then decide from there. If you have a cleaning company, you can ask them to provide green options or you can simply purchase a selection for them to use. The end result is that nothing toxic will enter your drains.

Even something as simple as cleaning the floors and toilets with green supplies can have a massive impact on the environment. When you choose to do what is eco-friendly, you also choose a future for both your company and the world. This is greatly appreciated by customers, so it’s worth sharing this with them through your social media or newsletters.

Hold Regular Energy Audits

Do you know where your energy is going? It takes a lot of resources to create electricity and that contributes to the carbon footprint of a manufacturing company. The more energy being used, the less eco-friendly the facility. There are multiple places that energy can be used and it’s best to know exactly where it is being used.

This includes:

Lighting: Your lights could be using large amounts of power if they’re not eco-friendly bulbs and fixtures. Take the time to switch to green lights and you’ll save money, as well as energy. There are ways to dim lights automatically so you’re not wasting electricity when no one is in the factory and you can also have lights come on automatically at dusk.

Temperature control: Are you heating or cooling areas of your property? If so, it’s a good idea to reduce how much you are using for temperature control. If it’s not necessary for product control, you should be able to change the temperature by a few degrees and reduce your energy costs.

Equipment: Your equipment will obviously be a big part of energy expenditure, but it can be helpful to understand exactly how much of your power usage goes to your equipment. You may need to upgrade your systems to ensure maximum efficiency.

These audits should be done at least twice a year to see exactly where your power goes. Then you can make adjustments as needed.

Switch to Sustainable Energy

Another way to save both money and improve ecological conditions as a manufacturing facility is to move to sustainable energy. For example, it’s possible to use solar panels to power the plant or you might decide to switch to wind power. The best option will depend on where your facility is located, as well as its power needs.

Areas that receive plenty of sun can benefit from solar panels, while wind turbines only work when there’s near-constant wind. Without these, you will need backup power to run the entire facility, which may come from the regular grid, or it could be from backup generators, which are not very green.

Moving to greener power can have an effect on the area around your site, as well. Not only does this reduce the amount of power gained via non-sustainable methods, it also encourages others to make the switch.

Recycling and Circular Manufacturing

You’re familiar with recycling already and this is a major way that manufacturing companies can go green. They can both recycle their waste and also create products that are recyclable. For example, drink containers can be made from recyclable materials to encourage the end-user to be greener, as well. You can use recycling as a way to be more responsible for the waste produced by your plant.

However, there’s another manufacturing method referred to as circular manufacturing, which is a new way to be as eco-friendly as possible. It involves re-using as many of the end products as possible and reducing the amount of material used to produce the products in the first place. Essentially, it’s a more efficient method of manufacturing, which benefits the company, the end-user, and the environment.

Manufacturers are also attempting to use their by-products more efficiently. For example, sawdust that is produced when a wooden product is made can be sold as bedding for animals. You’ll find that more and more companies are trying to make better use of their products and by-products. The end result is a greener company with less of an impact on the environment.

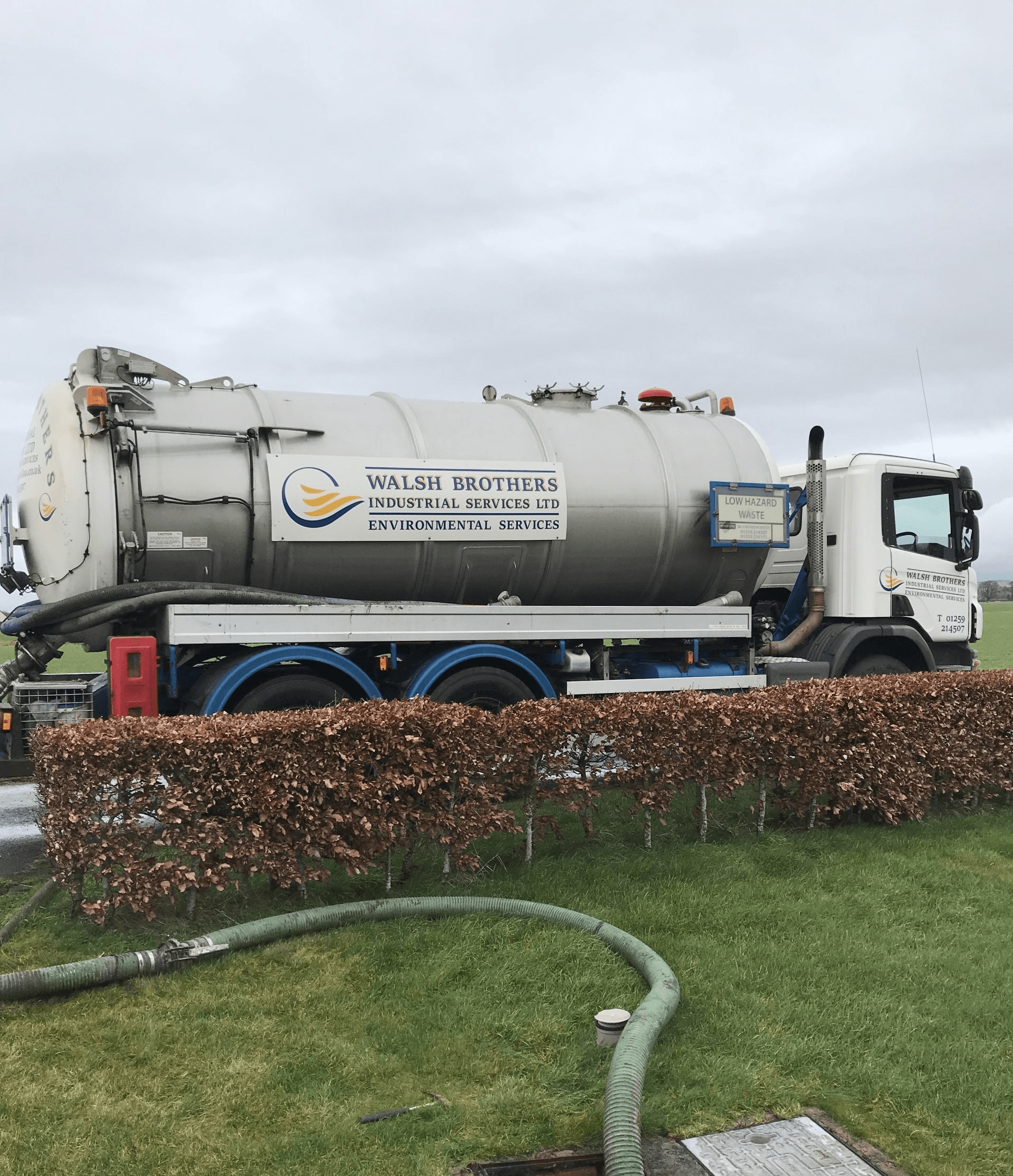

Hazardous Waste Management and Hazardous Waste Collection

Industrial waste management is a big topic these days. That’s because we’re realising just how much damage hazardous waste is wreaking on the world. Without proper disposal, the chemicals and toxins are simply leached into the air, water, and soil around us. Thanks to a number of unpleasant discoveries, we now know this is the wrong way to go about it. But how can manufacturing companies go green with their industrial waste collection?

Understanding the problem is the first step in going green.

Once companies understand that they need to be more careful with how they get rid of their waste, they can begin to research solutions. Sometimes that solution is to change the way things are done so that hazardous waste is no longer produced in the same quantities. In other cases, it means taking care to sort the rubbish so it will be handled properly. In either case, the industrial waste can be managed by a professional company with experts who know how to properly dispose of the items.

Even equipment that is being replaced can become hazardous if not properly taken care of. E-waste is a big problem with computers, phones, and more going to landfills every day. It’s possible to recycle many of the components in these machines and that will ease the load on the environment and make the entire process more eco-friendly. However, you should note that if your company does produce toxic by-products, it may be very difficult to dispose of them in a safe manner.

For this reason, a large number of companies are looking at new ways to develop their existing products. This means finding safe, less hazardous ways to manufacture their products, such as by using their waste over again or changing materials to something more eco-friendly.

If you do have hazardous waste that needs to be disposed of, it’s essential to do this properly. You should hire a company to manage your waste disposal for you so that you can be sure it’s done correctly and doesn’t weigh on those working at your facility.

Interested in learning more about industrial waste management? Contact Walsh Brothers Industrial Services today to learn more about what we offer.