How Can the Industrial Sector be More Environmentally Friendly

How Can the Industrial Sector be More Environmentally Friendly

The industrial sector covers a diverse range of industries, including manufacturing, construction, mining, agriculture, transport and more. Many of these industries aren’t known for being the most sustainable or environmentally friendly, but practices are changing.

After following advice from the UK Committee on Climate Change, the Scottish government made amendments to their Climate Change Bill, setting a target for net zero emissions of all greenhouse gases by 2045. All businesses have a responsibility to do their bit, particularly those who use a lot of energy, like the industrial sector.

Luckily, there are plenty of ways for the industrial sector to become more environmentally friendly, sustainable and reduce their greenhouse gas emissions. If you work in the industry or simply want to know how we can build a more sustainable future, read on to find out more.

Use renewable energy

Switching to renewable energy is one of the best ways to improve sustainability in the industrial sector. The construction industry alone is said to contribute 23% of all air pollution, 50% of landfill waste and 40% of drinking water pollution. These statistics have a serious negative impact on our environment but choosing renewable energy is a great place to start making changes.

There are many different renewable energy power sources, including solar, wind, hydro and biomass. Renewable energy is clean, sustainable and infinite, and it reduces the need to rely on fossil fuels like oil or gas. Renewable energy can also save businesses money by reducing their energy bills, or through government schemes to help businesses switch to greener power.

If some industrial industries aren’t ready to make a full switch to renewable energy, there are hybrid options available. This equipment switches between electricity and conventional fossil fuels but it’s still much better for the environment.

Sustainable manufacturing

Sustainable manufacturing is the creation of products using processes that minimise negative impacts on the environment. It would be easy to write an entire book on sustainable manufacturing (!) but some of the basic principles are things like:

- Using renewable energy in the manufacturing process

- Reducing waste

- Reducing water use

- Sourcing ethical ingredients/materials

- Using less packaging

- Conserving natural resources.

Sustainable manufacturing has many benefits for businesses across different industry sectors, as well as the environment. Proven benefits include increased operational efficiency, improved reputation, greater customer satisfaction and a wider reach for new customers.

Reduce and reuse waste

Businesses should aim to reduce and recycle as much waste as possible to avoid sending waste to landfill. It’s estimated that the UK produced over 40 million tonnes of commercial and industrial waste in 2016 alone, so it’s important for all businesses to play their part.

Start by measuring your waste to see if there are any areas where you could cut back. This could be by reducing the amount of packaging you produce, choosing recycled packaging or cutting down on food waste. A waste exchange is another great option for the industrial sector. You might have a material that’s waste to you, but could be utilised as a resource in another business’s manufacturing process. Similarly, they might have something that you could use, allowing you to reduce the amount of raw resources used and ensure your waste is reused in a productive way.

Energy audits

Industrial industries like manufacturing use huge amounts of energy to power their everyday operations. Energy production and consumption has a negative impact on our environment in several ways, including air pollution, water pollution and climate change. It’s impossible to cut out energy altogether, but you can monitor how much you’re using with regular energy audits.

Energy audits can monitor how much energy is being used by each piece of equipment (or workplace zone). You can then use this information to identify where and how you could become more energy efficient. This could include switching to renewable energy sources, swapping fluorescent bulbs for LEDs or adding more insulation to the building.

Proper hazardous waste disposal

The industrial sector produces large amounts of hazardous waste, including oils, acids, paints, fuel, industrial solvents, batteries and fluorescent lights. Improper disposal of this type of waste is extremely harmful to the environment and it’s illegal too.

In Scotland, this type of hazardous waste is known as special waste and there are rules and regulations which must be followed. Businesses have a responsibility to classify the waste they produce and then ensure that it’s disposed of in an authorised way. All special (hazardous) waste produced in Scotland must be consigned using a SEPA-issued consignment note or code, regardless of its final destination within the UK.

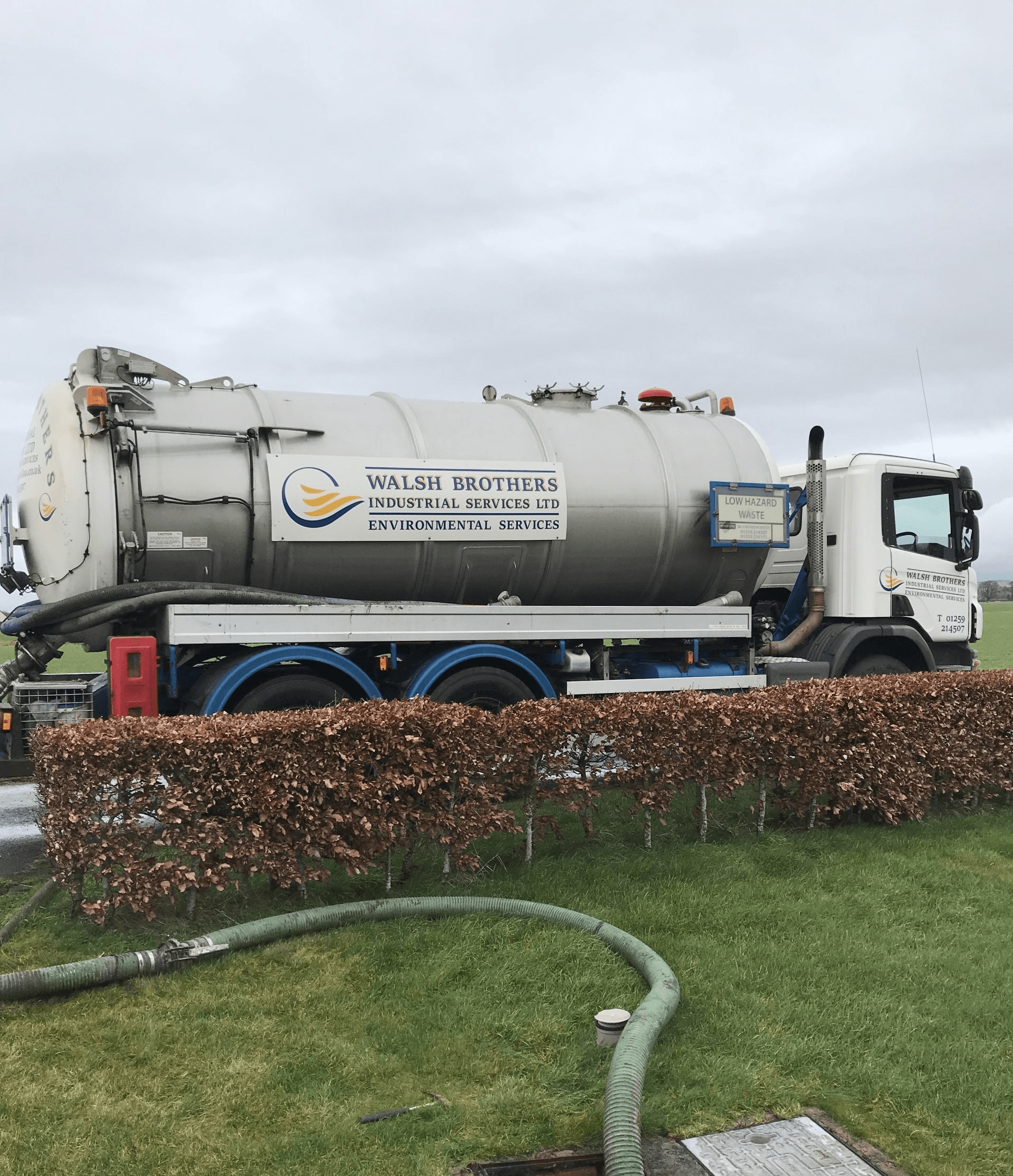

Many businesses won’t have a licence to dispose of hazardous waste themselves, so it’s essential that you choose a professional company to collect and dispose of the waste on your behalf. Look for a SEPA registered company who will have all the knowledge and expertise needed to handle hazardous waste in a safe, environmentally friendly way.

Businesses should never dump hazardous waste at an unauthorised landfill, in a river or in any public place. This can be classed as fly tipping and you could receive a fine or even a prison sentence, not to mention the damage it would do to the environment.

Choose eco-friendly partners

Many businesses need to work with partners, especially if you work in an industry like manufacturing or construction. Your business might be committed to being environmentally-friendly but you can go one step further by choosing partners who share these values. This could be something like switching to a packaging manufacturer who uses recycled materials, or choosing companies who are committed to using renewable energy.

Upgrade your insulation

Many industrial businesses operate in large warehouses or factories and a huge amount of energy is often required to heat these buildings. As discussed, this isn’t great for the environment, but upgrading your insulation is a highly effective way to improve a building’s energy efficiency.

There are many options to choose from, including roof insulation, internal or external insulation for walls, draught proofing or thermal cladding for pipes. You could even add something like a green roof to improve a building’s heating and cooling efficiency and maintain a stable temperature all year round.

Update machinery and equipment

The industrial sector relies on a huge variety of machines and equipment but when did you last replace your machines? Older machinery might still get the job done but chances are that it’s using more energy than necessary. Updating your equipment could reduce your energy usage and increase productivity levels so it’s definitely something to consider.

More efficient equipment is also less prone to errors, allowing you to cut down on wastage too. Another option is to install an electrical power management system (epms). This allows businesses to identify, track and address any wasteful energy practices for maximum efficiency.

Professional industrial waste management from Walsh Brothers Industrial Services

If you’re in need of professional hazardous waste disposal, get in touch with the experts at Walsh Brothers Industrial Services. We’re a SEPA licensed service with over 40 years of experience serving customers across Glasgow, Edinburgh, Fife, Stirling, Aberdeen and more. We offer a fully compliant hazardous waste disposal service for your peace of mind, as well as responsible waste collection.

We can collect and dispose of a full range of industrial waste, including oils, acids, industrial solvents, fuel, paints, coolants and more. We also offer septic tank emptying and cleaning, industrial cleaning and oil tank cleaning to keep your business running smoothly. For more information about our hazardous waste disposal or any of our other services, don’t hesitate to give us a call or contact us online.